Author

DSH Systems produce unique loading spouts to cover a wide range of applications. Due to international demand, the company is constantly researching and developing systems to enable the efficient transfer of a wider range of products. The top of the range PFC (programmable feed control) system automatically configures the hopper for variable product weights, while the basic system requires no utilities for operation.

After years of f

, their award winning Dust Suppression System works at peak efficiency. So it is no surprise that companies around the world are eager to reap the benefits of this internationally tested and superior system.

Extensive research proves the DSH System works well on many different dry, free-running, granular products. Academic interest from international universities and consultants continues to expand upon the research and science behind this revolutionary system.

How does the Dust Suppression System work?

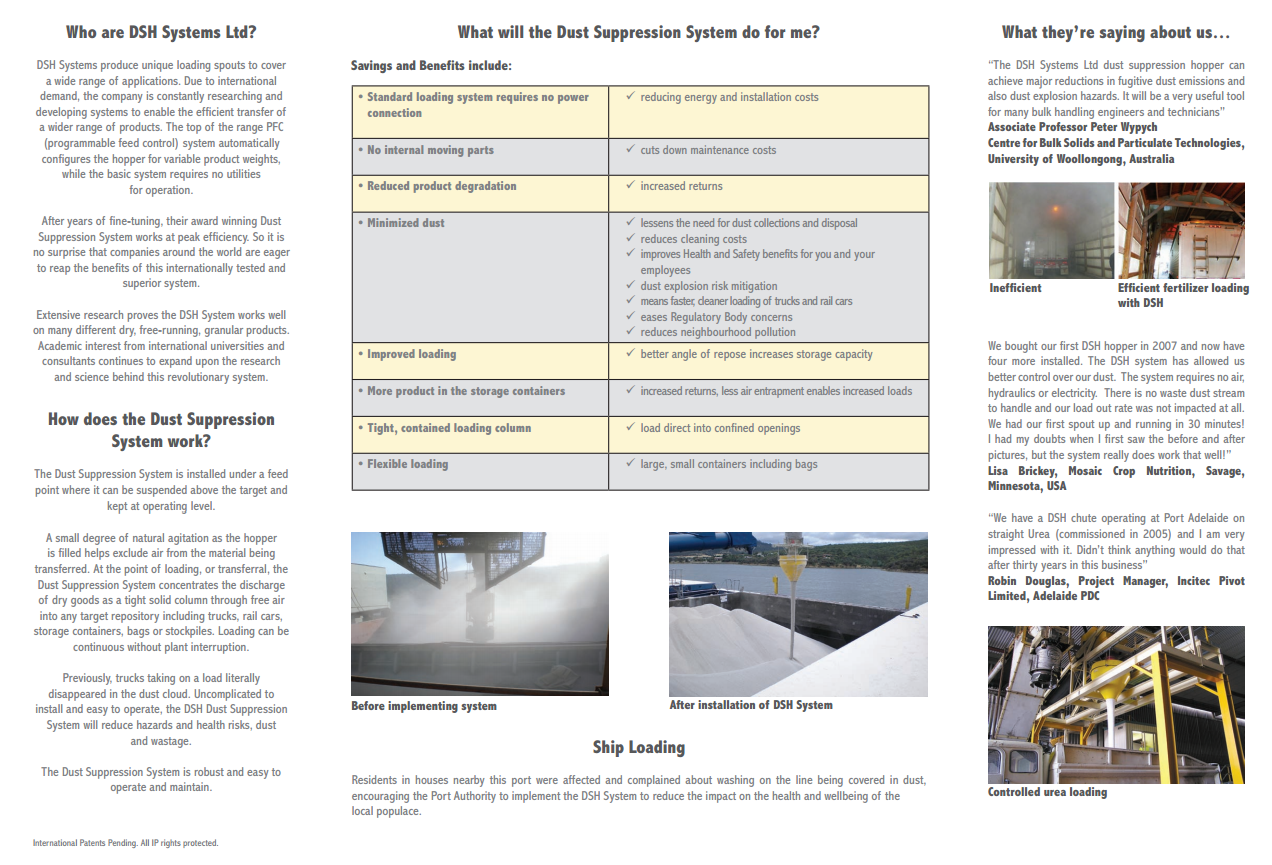

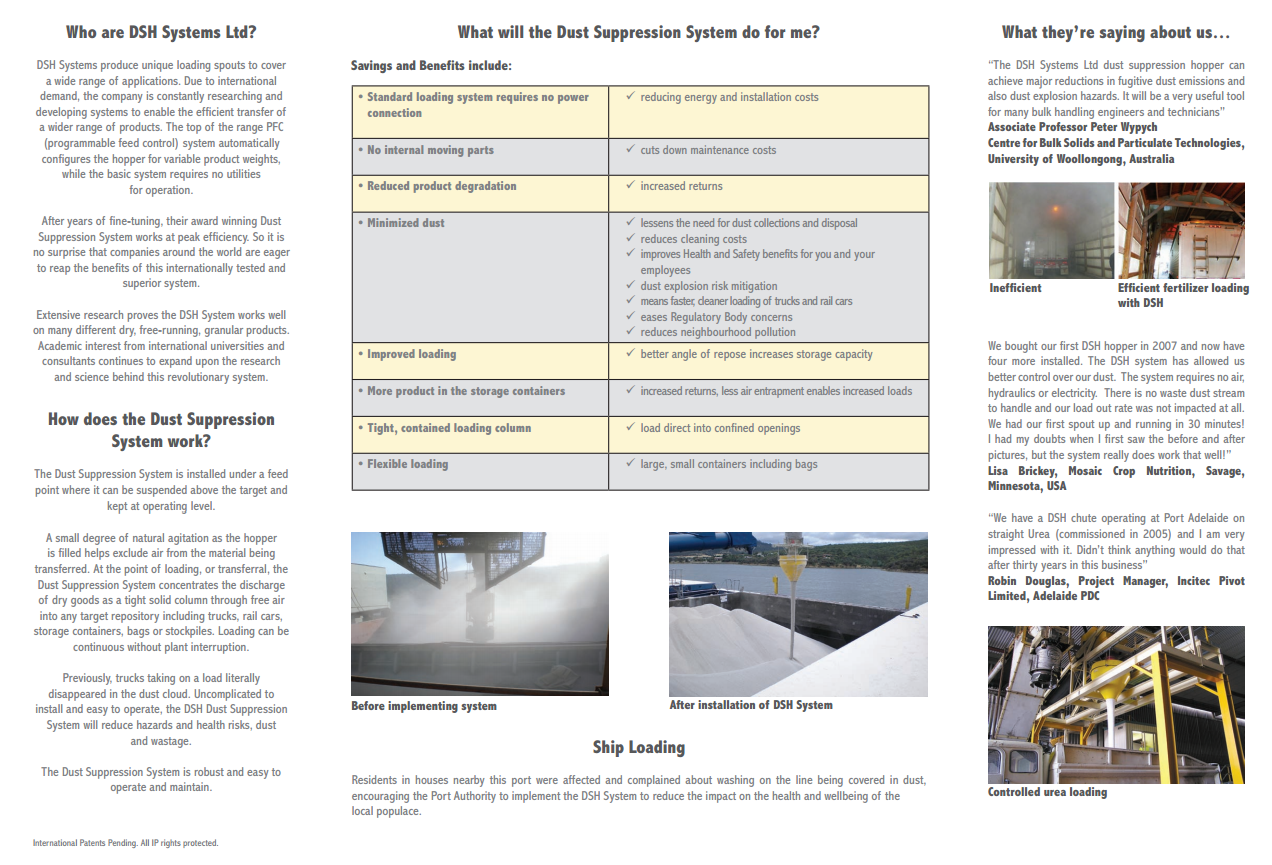

The Dust Suppression System is installed under a feed point where it can be suspended above the target and kept at operating level. A small degree of natural agitation as the hopper is filled helps exclude air from the material being transferred. At the point of loading, or transferral, the Dust Suppression System concentrates the discharge of dry goods as a tight solid column through free air into any target repository including trucks, rail cars, storage containers, bags or stockpiles. Loading can be continuous without plant interruption.

Previously, trucks taking on a load literally disappeared in the dust cloud. Uncomplicated to install and easy to operate, the DSH Dust Suppression System will reduce hazards and health risks, dust and wastage.

The Dust Suppression System is robust and easy to operate and maintain.

After years of f

Extensive research proves the DSH System works well on many different dry, free-running, granular products. Academic interest from international universities and consultants continues to expand upon the research and science behind this revolutionary system.

How does the Dust Suppression System work?

The Dust Suppression System is installed under a feed point where it can be suspended above the target and kept at operating level. A small degree of natural agitation as the hopper is filled helps exclude air from the material being transferred. At the point of loading, or transferral, the Dust Suppression System concentrates the discharge of dry goods as a tight solid column through free air into any target repository including trucks, rail cars, storage containers, bags or stockpiles. Loading can be continuous without plant interruption.

Previously, trucks taking on a load literally disappeared in the dust cloud. Uncomplicated to install and easy to operate, the DSH Dust Suppression System will reduce hazards and health risks, dust and wastage.

The Dust Suppression System is robust and easy to operate and maintain.